Pace Industries Announces Doug Albert, as Chief Executive Officer

Pace Industries, LLC (“Pace” or the “Company”), North America’s leading full-service aluminum, zinc and magnesium die casting manufacturer, today announced that Doug Albert has been appointed as Chief Executive Officer.

Mr. Albert brings more than 20 years of leadership experience in the industrial sector, having served in a range of general management, commercial, manufacturing, financial, and operational roles. From 2014 until its sale in 2022, Mr. Albert was the President and Chief Executive Officer of Resco Products, Inc., a leading North American manufacturer of refractory products serving steel and industrial end markets. At Resco Products, he oversaw key strategic initiatives that drove growth and improvements in commercial, operating, and financial performance.

“Doug is a seasoned leader bringing a deep understanding of our customers, markets, and industry,” said Jeffrey P. Pritchett, Executive Chairman of Pace. “His knowledge, combined with an impressive commercial and operational background, makes him a great fit for Pace. Alongside our talented team, Doug will help Pace become an even stronger partner to our customers and expand in our core markets. We’re thrilled to have him at the helm in this next chapter of growth for Pace.”

Prior to Resco Products, Mr. Albert held leadership positions at Environmental Filtration Technologies and GE Fanuc Automation. Earlier in his career, he spent several years at global consulting firm Booz Allen where he supported a broad range of companies on manufacturing and supply chain management strategies. Mr. Albert earned a B.S. in Mechanical Engineering from the University of Rochester and received an MEM and MBA from Northwestern University’s McCormick School of Engineering and its J.L. Kellogg Graduate School of Management, respectively.

Mr. Albert added: “Pace has been a trusted partner for more than 50 years because of its unwavering commitment to quality and value. This is a dynamic time for the Company, and I’m excited to join the dedicated team. Together, we’ll strengthen our platform, accelerate our commercial strategy, and expand in strategic markets. I’m grateful to Pace’s Board and shareholders for their support and look forward to delivering best-in-class service and great value to customers.”

Pace is remarkably proud of our recognition by the National Aluminum Die Casting Association (NADCA). Multiple divisions within the company received NADCA Safety Awards this year, which marks 12 consecutive years we have received these prestigious industry awards.

Pace is remarkably proud of our recognition by the National Aluminum Die Casting Association (NADCA). Multiple divisions within the company received NADCA Safety Awards this year, which marks 12 consecutive years we have received these prestigious industry awards.

My name is Eve Mayer and I don’t work in die casting. I am an author who works in social media, the world of words where everything we create can neither be touched nor felt with the human hand.

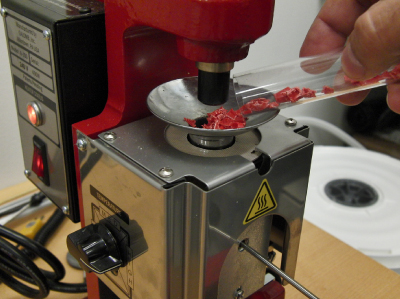

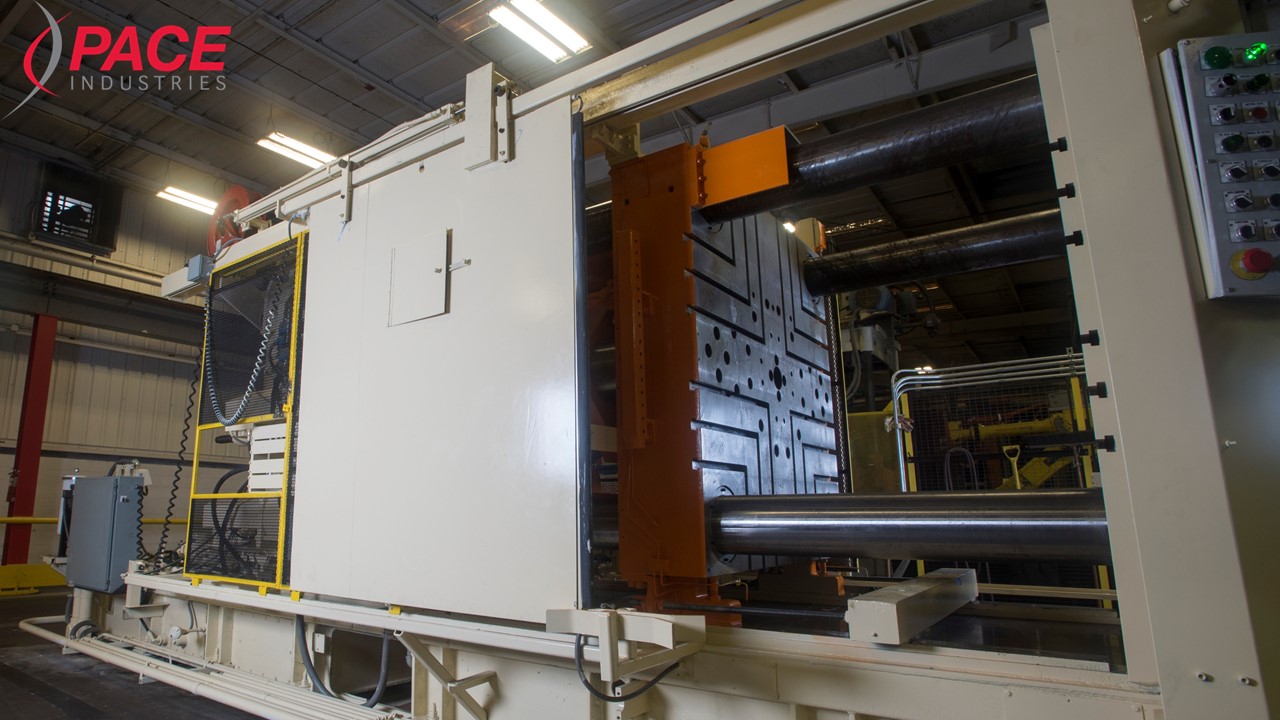

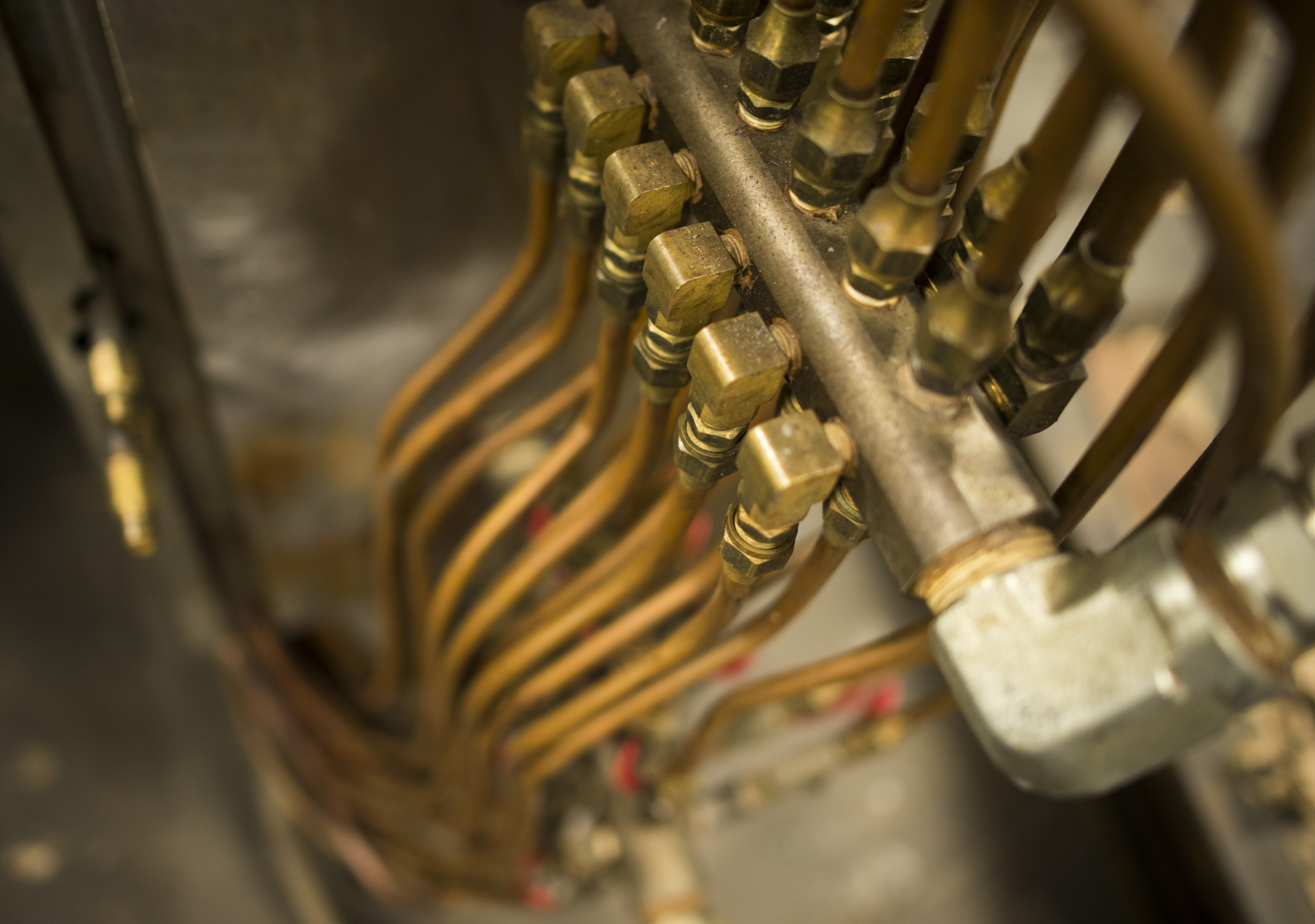

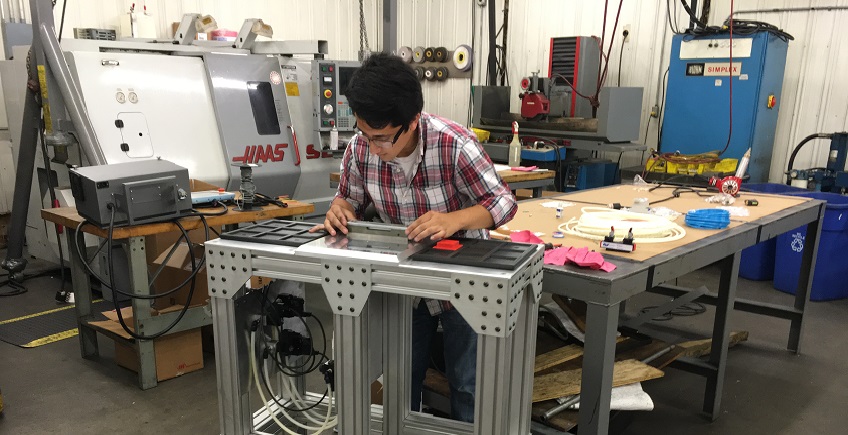

My name is Eve Mayer and I don’t work in die casting. I am an author who works in social media, the world of words where everything we create can neither be touched nor felt with the human hand. Die casting isn’t a glamorous industry. It is a detailed, precision necessary industry where hard working people use machines to carefully craft metal pieces like auto parts, light bulb bases, motorcycle pieces, back sides of carpeting and bed springs. My view is probably skewed as I toured an aluminum factory and die casting is done with several different types of metals like zinc, magnesium and aluminum.

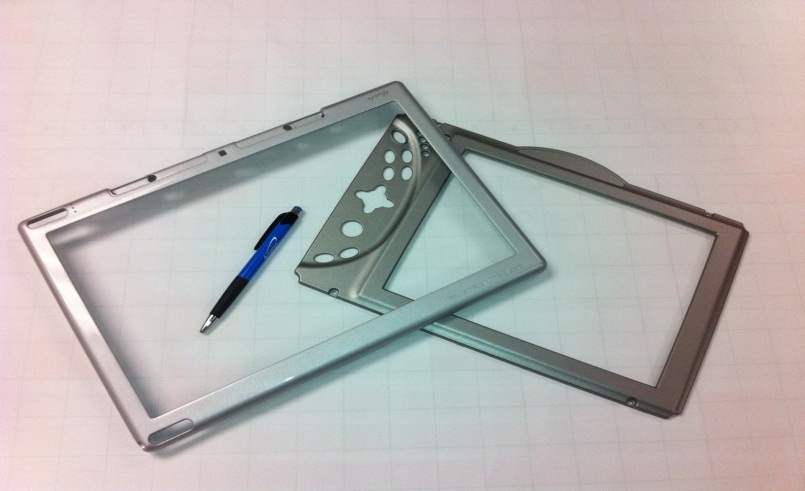

Die casting isn’t a glamorous industry. It is a detailed, precision necessary industry where hard working people use machines to carefully craft metal pieces like auto parts, light bulb bases, motorcycle pieces, back sides of carpeting and bed springs. My view is probably skewed as I toured an aluminum factory and die casting is done with several different types of metals like zinc, magnesium and aluminum. Some metal pieces need to be pretty and some don’t. For example, if you are having a piece built for the inside of a car engine that someone will never see once built, you don’t want to spend money on making this piece pretty, it just needs to be functional. Another metal piece might be on a motorcycle but sit on the outside of the bike in full view so it needs to be functional but also have a nice look to it. This is where specific processes that deal with painting or chroming parts comes into play.

Some metal pieces need to be pretty and some don’t. For example, if you are having a piece built for the inside of a car engine that someone will never see once built, you don’t want to spend money on making this piece pretty, it just needs to be functional. Another metal piece might be on a motorcycle but sit on the outside of the bike in full view so it needs to be functional but also have a nice look to it. This is where specific processes that deal with painting or chroming parts comes into play.