MEET THE STAFF

EXECUTIVE TEAM

PACE COMMITMENTS

OPERATIONAL EXCELLENCE

Operational Excellence is a mindset with strategic focus on Customer, Capabilities, and Cost ensuring solid foundational elements.

DIVERSITY, EQUITY & INCLUSION

DEI is vital to creating and maintaining a successful workplace; one founded on the principle that all people can thrive personally and professionally.

SUSTAINABILITY

Manufacturers across industries rely on Pace for the best die cast parts. As a supplier and partner, Pace can also be relied upon for a commitment to sustainability.

PACE COMMITMENTS

OPERATIONAL EXCELLENCE

Operational Excellence is a mindset with strategic focus on Customer, Capabilities, and Cost ensuring solid foundational elements.

DIVERSITY, EQUITY & INCLUSION

DEI is vital to creating and maintaining a successful workplace; one founded on the principle that all people can thrive personally and professionally.

SUSTAINABILITY

Manufacturers across industries rely on Pace for the best die cast parts. As a supplier and partner, Pace can also be relied upon for a commitment to sustainability.

COMPANY HISTORY

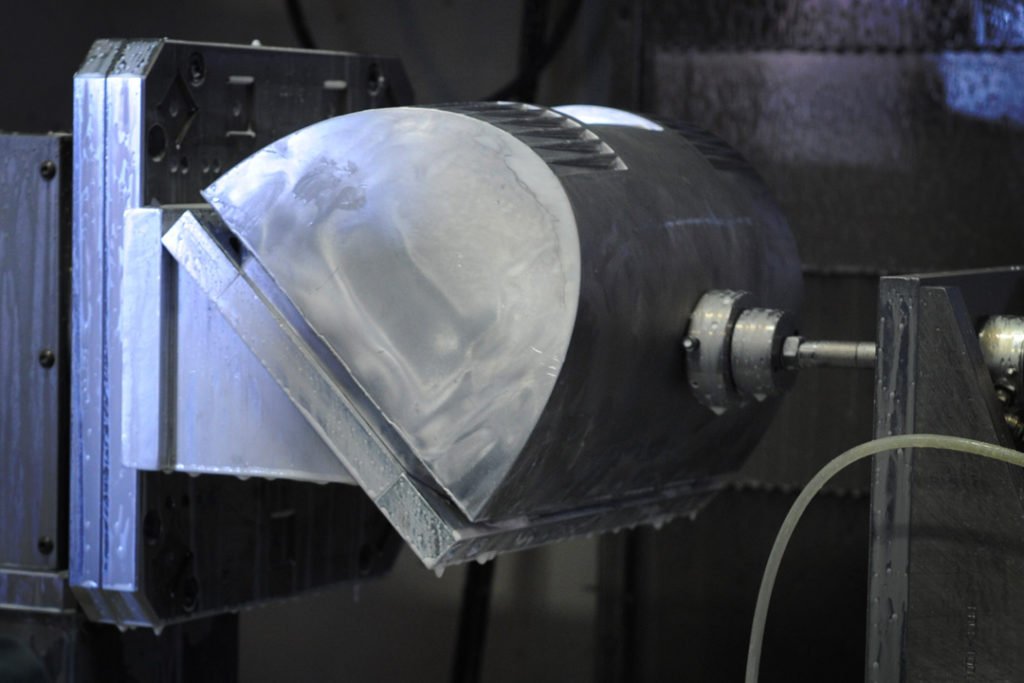

Pace Industries was founded in 1970 with a small die casting facility located in Harrison, AR. Today Pace is the 5th largest general industrial castings company in North America and the #1 independent die casting company in North America with expertise in aluminum, magnesium and zinc. Pace offers a wide array of services and capabilities to customers across numerous markets including: automotive, commercial vehicle, powersports, lighting, lawn and garden, appliance, aerospace, defense, medical, and other industries. But, more important than size, the culture of Pace provides the foundation for a business dedicated to, and which delivers, uncompromising and uncommon service, business excellence and integrity.