20 Years of Growth

Ever since it was founded in 1970, Pace Industries has been committed to providing uncommon, creative die casting and support solutions to their customers. While our goal has always been the same, the tactics for achieving it have understandably changed, especially when looking at the last 20 years.

Predictive Analysis

It was important for us to constantly improve the design of our tools to ensure we were providing the highest quality products to our customers. Starting in 1996, we began to employ the following analyses to better understand our designs:

- Flow analysis – shows the flow pattern during die cavity fill. Reveals temperature, pressure, and velocity.

- Thermal analysis – shows how the metal solidifies within the steel die.

- Thermal stress analysis – shows how the castings distorts as it cools after being removed from the die.

- Finite element analysis (FEA) (added in 1998) – analyzes high stress areas in castings which can be used to improve strength of future castings.

We often have a new cast tool running with changes implemented within six months of studying insights from the analyses.

Die Life Guarantees

Thanks to research done by NADCA, we began to understand how to optimize die steel performance in the casting process. This was information that affected our language when communicating with customers about the length of die life. We took the research and successfully applied it to our process in the late 90s. How successfully? Well, prior to that, several of our tools were suffering premature failure yearly. Since that implementation, there hasn’t been more than two failures in over five years.

New Alloys

In order to offer even more abilities to our customers, we entered the new millennium with the development of several new specialty alloys:

- High elongation aluminum alloys – for use in thin-wall structural applications. This plays a major role in helping reach mandated fuel efficiency levels for automotive companies.

- Specialty aluminum alloys – allows the die casting process to compete with other aluminum processes that standard die castings cannot meet.

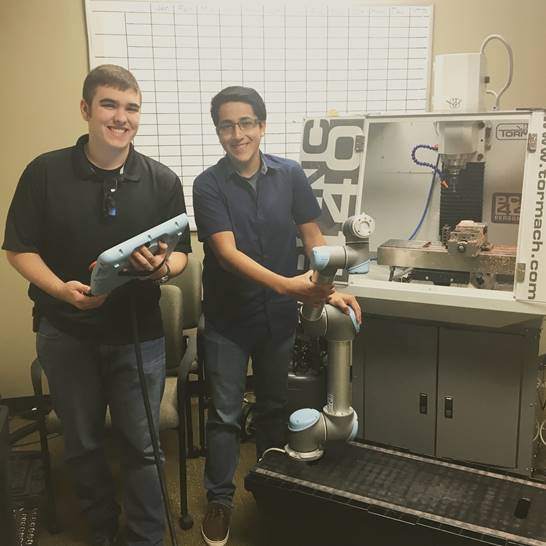

Automation

We are devoted to making sure we are using the most efficient technology, and our increased use of automation has led to some groundbreaking developments. In 2013, we began to use dosing furnaces that led to energy savings, and in 2002, we saw emphasis on the use of robots. There was a learning curve for our associates during this time, with many requiring training on the new methods, something that was surprisingly enjoyable. “Most of our people enjoyed the training because it was a challenge, and several requested to work with the robots,” said Arnie Fulton, vice president of engineering.

Furnace Design

In early 2004, we began to examine the best design that would lead to increased energy efficiency and melt rate. In five months, we had reached our goals by improving insulation, improving refractory, and applying a new burner design and molten metal pumps. In the time since, we have built approximately 15 more furnaces, all using the same effective design as that first one.

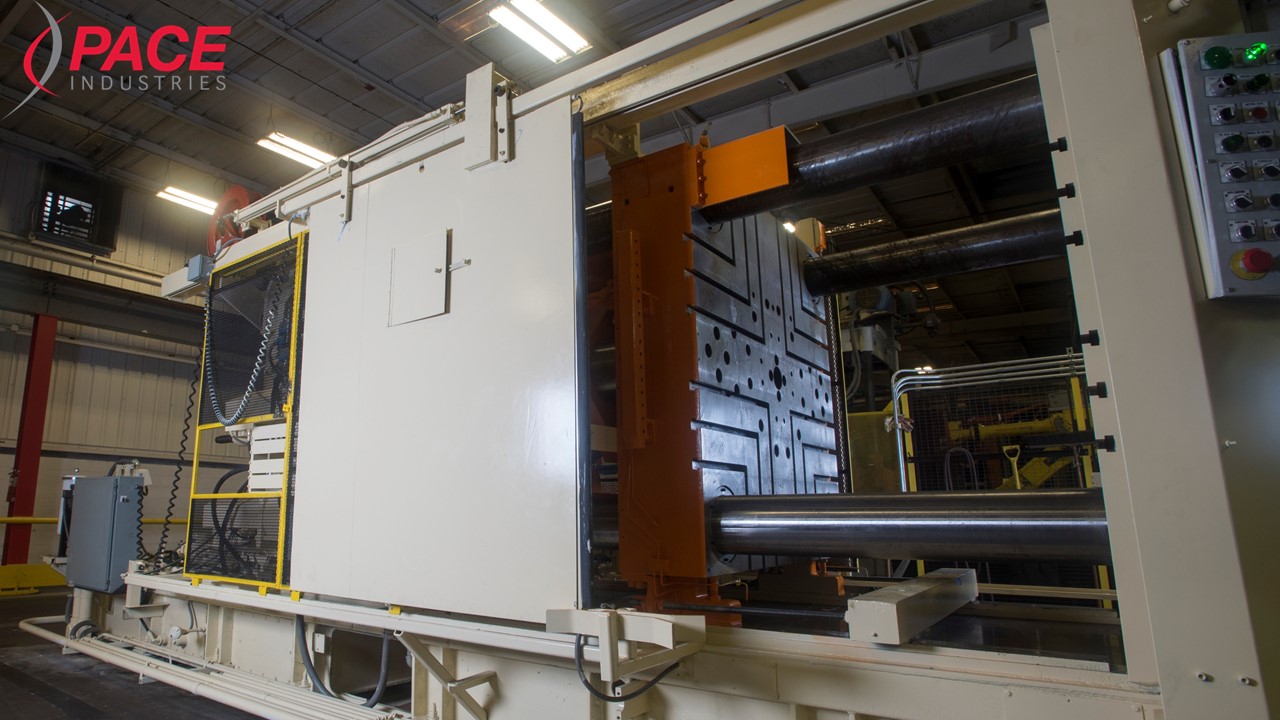

Bigger Die Cast Machines

In 2015, customer needs required bigger machines than what we had. To continue to best serve our customers, we worked to acquire machines up to 3,000 tons, when our previous leading machine maxed out at 1,800. This change maximized satisfaction and allowed us to foray into new areas such as alternate alloys.

The past 20 years have brought tremendous growth to our company, our associates and our customers. But we aren’t stopping. We are excited about what will come in the next 20 years.