Five Things You May Not Know About Aluminum

Five Things You May Not Know About Aluminum

When most people think of aluminum, it’s in reference to a soda can or long strips of foil used in the kitchen. An interesting thing about aluminum is that it’s actually found in many places, such as doorknobs, kitchen utensils and even glass production. And it continues to gain traction in many industries.

According to the Aluminum Association, it has been produced in commercial quantities for just over 100 years, which makes it a comparatively new industrial metal.

What makes aluminum so popular?

In addition to being the second most abundant metallic element in the Earth’s crust next to silicon, it’s easy to mold, fold and recycle. This creates a long list of benefits for things like packaging, transportation and construction.

With Pace being an aluminum die casting company, you can imagine our appreciation of this prevalent element. We believe the more that’s understood about the benefits and uses of aluminum the more we can innovate and advance technologies around this plentiful resource.

With that in mind, we’d like to share a few interesting facts.

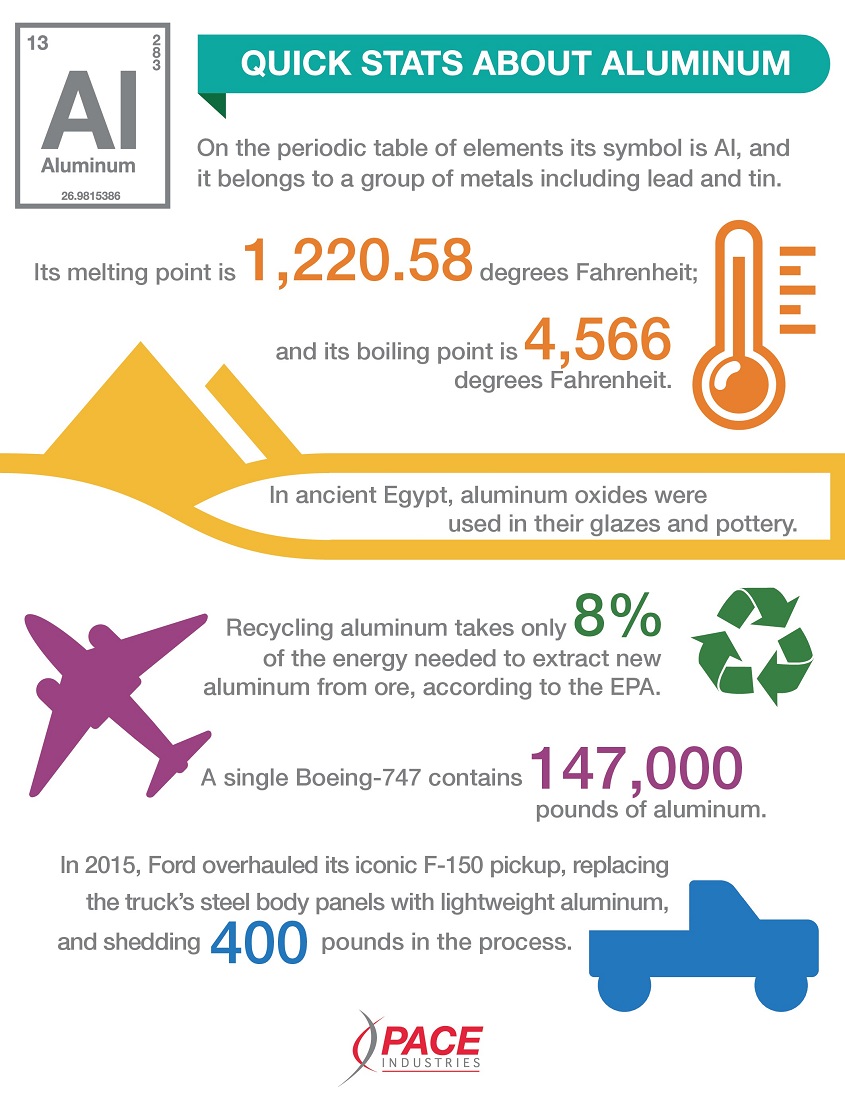

- Aluminum is green. There are two types of aluminum: primary and secondary. Primary production is the process by which new aluminum is made. Secondary production is where existing aluminum is recycled into another usable form. This secondary process is extremely environmentally friendly. In fact, it’s 92 percent more energy efficient than primary production.With the ability to recycle aluminum so easily, there isn’t a high demand for mining new resources. The Aluminum Association reports that 75 percent of aluminum ever made is still in use. In our own operations, Pace uses only recycled aluminum. It’s more cost effective and also a responsible way to operate.

- Aluminum is extremely lightweight. According to the S. Geological Survey, it’s a third of the weight of steel or copper. What this means for Pace is that it allows us to have greater design capabilities. We can develop products that allow for lightweighting, which is critical for many of our customers – especially those in the aircraft, boating and automobile industries. Lighter machines translate to less energy required to operate.

- Aluminum plays well with others. The unique properties of aluminum alloy allow the metal to work well with a steel die, which is what Pace uses. The process moves quickly with aluminum, and we’re able to get fine details on a part. This can eliminate secondary operations and allow us to combine parts. That means less assembly for castings that are lower cost and with a finer detail.

- Aluminum was born out of science. Aluminum isn’t naturally found in the Earth’s crust. It comes from bauxite, which has to be processed to get aluminum. What this means is that it required the efforts of chemists and engineers to bring it to life. Essentially, innovation made this metal possible.As an interesting fact, Danish chemist Hans Christian Oersted first extracted aluminum from alum in 1825. It remained a novelty and too expensive to mass-produce until 1886 when American chemist Charles Martin Hall and French chemist Paul Héroult independently invented the Hall-Héroult process, which is still used today.

- Aluminum is getting stronger. Scientists continue to search for ways to improve aluminum, and there are currently hundreds of mixes on the market. One of the most recent breakthroughs was in 2010. Yuntian Zhu, a professor at North Carolina State University, and his colleagues subjected aluminum with magnesium and zinc to extreme pressure. The result was an aluminum that’s as strong as steel.The next phase of development is to produce this in large enough volumes for commercial applications, which will be a game changer for many industries.

With so many applications and unique benefits, it’s easy to classify aluminum as the metal of modern life. We’re excited to continue innovating with this resource and watch how it will transform the world around us in years to come.

For a complete history of aluminum, check out this article by the Aluminum Association.

Thank you for providing this information about aluminum. I did not know that this material was made from science and that it does not exist naturally in the earth’s crust. Something to consider would be to use this man made steel in everyday life. It would be best to find aluminum that can be purchased for a price within your budget.

I had no idea that aluminum was getting stronger and stronger today, sometimes comparable to steel. It’s good to know this so that we can be more comfortable with making use of aluminum, especially with bigger jobs, such as with fuel tanks. That way, you can be more confident in making use of aluminum both for it’s sturdiness and for it’s unique resistant properties.

It’s interesting to learn that the secondary production of aluminum to make it usable for us can be helpful to the environment due to its quick recycling process and efficiency. Speaking of which, my brother has plenty of items made up of aluminum that he hardly touches in the garage. He’s meant to throw it all away but good thing you shared in your post that it can be recycled and safe to the environment. I’ll have a word with him and see if he can look for scrap metal companies that can accept them at a just price!

A good blog that you shared with us and it is very knowledgeable, is aware of some things we do not know.

It’s cool that aluminum is very recyclable. My uncle does construction work and such. I wonder if he uses recycled aluminum.

It was really informative when you mentioned that aluminum is a green material. I would imagine that businesses would like to use aluminum when constructing a building. Using green materials would help a business know that it is helping the environment.

So, how did someone know enough to take boxite and chemically process it down to produce alumina and then submit it to high voltage electrical process to generate a final product called aluminum? How did that happen?