The Benefits of Magnesium Die Casting

Jim Hegland

Director of Sales

My background in the die cast industry up until 1995 was centered on aluminum and zinc. About that time, I was offered an opportunity to work with some people who had a desire to start up a Magnesium Die Cast operation. It sounded exciting, but wait a minute; I didn’t know a thing about magnesium. I started reading and absorbing everything I could find on the subject and quickly realized most everything available at that time had been published 10 to 20 years earlier. The common denominator I came up with was that there were plenty of issues with magnesium – most notably, that magnesium burns at an incredibly high temperature and corrodes. At this point, I thought, this might be a tough sell.

It was difficult at first because we were centered on the challenges we had heard about and not on the positives, which we quickly realized. We soon began to see that the two main issues, flammability and corrosion, were only partly true. A lot of things burn and corrode, it’s all in how you process it and work with it. Both of these conditions have proven to be controllable and can be overcome with proper processes and techniques that allow you to focus on the significant benefits of magnesium.

The real benefits of Magnesium Die Cast fall into two categories: processing and material specific.

Processing Magnesium

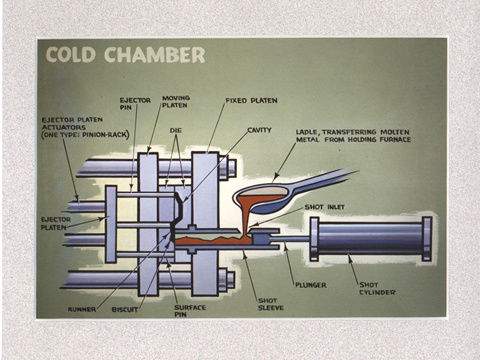

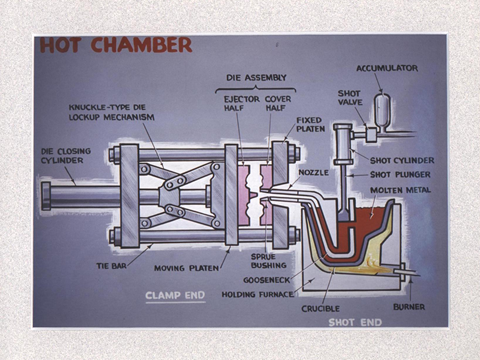

In our business there are 2 basic style machines: Hot Chamber and Cold Chamber.

The Hot Chamber Process we use has several benefits.

1) With Hot Chamber the molten metal is enclosed in a sealed furnace greatly reducing the risk of a fire. 2) With Hot Chamber the process time is 25-40% faster than the conventional Cold Chamber

3) Hot Chamber casting reduces recyclable scrap by 30-50% versus Cold Chamber.

4) Lower injection pressure, which equals better tolerance control for precision parts.

5) Hot Chamber casting prevents many porosity-type defects.

Material Benefits of Magnesium

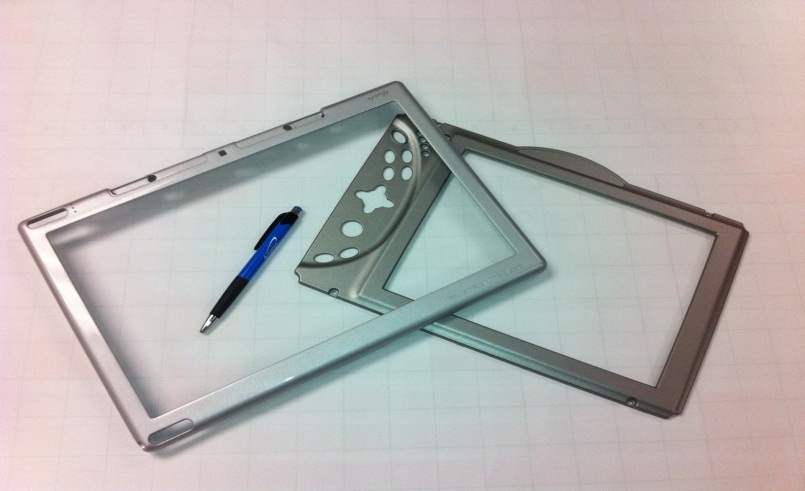

The ability to cast fine details, plus the advantage of very thin wall sections gives magnesium a significant advantage over other castable metals. With magnesium, you have an automatic 35% reduction in mass/weight over aluminum. If you combine that with thinner walls you may be 50% lighter. These benefits give magnesium a clear advantage on highly cosmetic parts.

Our experience with magnesium has provided evidence that this material gives the best dimensional part-to-part consistency mostly due to the quick solidification time and a natural lubricity that keeps it from sticking in the mold.

Magnesium machines very nice and with the very low cutting pressure required; very close tolerances are achievable. This low-cutting pressure also significantly lengthens the life of perishable tooling such as end mills, taps and drills.

These benefits go beyond cosmetic parts. All of these advantages apply to many industries. In automotive applications, the fact that magnesium reduces vibration 25 times better than aluminum gives this material a clear advantage by reducing road vibration. Most steering wheels made today have a Magnesium core over-molded with vinyl. This improves driver comfort by stopping the vibration from reaching your hands.

In any other industry that requires very tight tolerances, magnesium can often times be less expensive than the other cast metals by eliminating machine operations and provide many “as cast” features. When you combine this with the fact that magnesium die cast tooling lasts 2-3 times longer than aluminum tooling, some tangible advantages start to develop.

At the end of the day, the customer is the ultimate decision maker on what material they use. Giving them the options is my job. Over the years, many of our associates have asked me, “Jim, why does this part need to be magnesium?” Being a sales guy, my answer is, “That’s what we do.”

This blog has wonderfully explained about processing and benefits of Magnesium die castings.Thank you for sharing .

That’s cool that magnesium machines will be able to keep their perishable tooling like drills lasting long because they use low-cutting pressure. I think that this would be really helpful if you needed to cast any sort of product like industrial equipment or something else. You’d just need to find the right place that does magnesium die casting.