Maker Movement

Why the Maker Movement is Critical to our Future

There’s a trend that has been growing for several years now called the Maker Movement. It’s a modern term to describe the wave of independent inventors, designers and tinkerers who are bringing their ideas to market through the use of new technology.

Typical interests of a maker include engineering-related activities, such as electronics, robotics and 3D printing, which is why Pace is so interested in this movement. We’re constantly evolving in our use of technology to make the highest quality and most cost-effective products for our customers. We’re always improving our processes and strengthening our future. And one of the best ways to stay on course is to find and hire the best of this new generation of makers and give them resources to create industry-changing ideas.

Throughout history, when people have the right tools and inspiration, they have the ability to change the world. That’s what we’re experiencing right now. New tools like 3D printers, laser cutters and open-source hardware, are empowering a generation who have been tinkering in their garages and basements since they were little. It’s up to manufacturers, like us, to encourage these inventors to become team members. They hold the recipe for products of the future, and manufacturers have the means to produce them and make them work. It’s the perfect partnership.

So how do we encourage the Maker Movement and this generation of tinkerers to become part of a company like Pace? We invest in them and provide opportunities to explore and grow.

Investing in the Next Generation

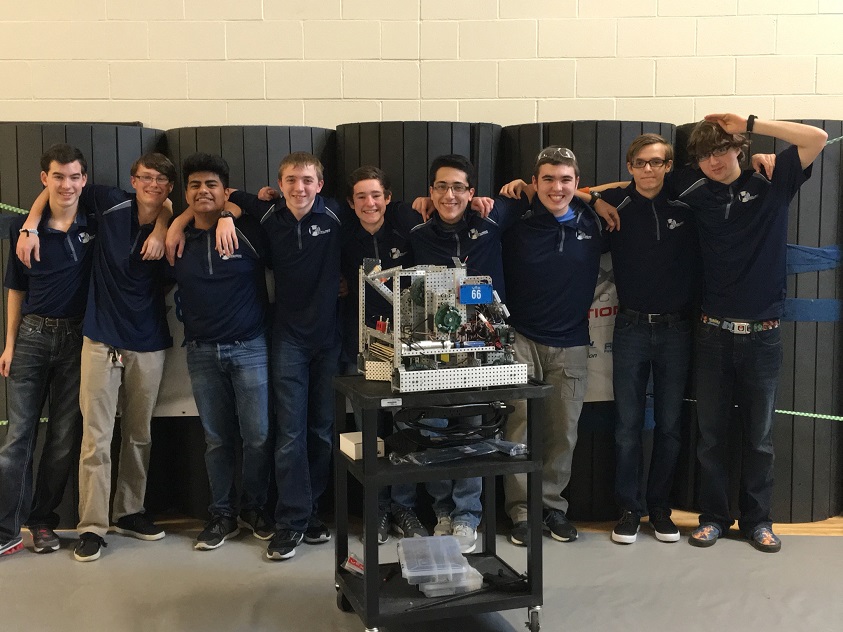

Pace is so committed to young engineers that we have created one-of-a-kind internships for kids as young as 15-years old. We also sponsor high school robotics teams and provide scholarships to college-level students interested in manufacturing. Our ultimate goal is to transform kids’ passions for engineering, robotics and other technologies into real-world business practices. We want to give them a place to grow – and a future to be excited about.

One of our inaugural programs has been an 8-week summer internship for two high school students. Juan Zuniga and Noah Wehn, both seniors at HarBer High School in Springdale, Ark., have been blazing trails since the day they started their internship with us. This is now their second summer to work with Pace.

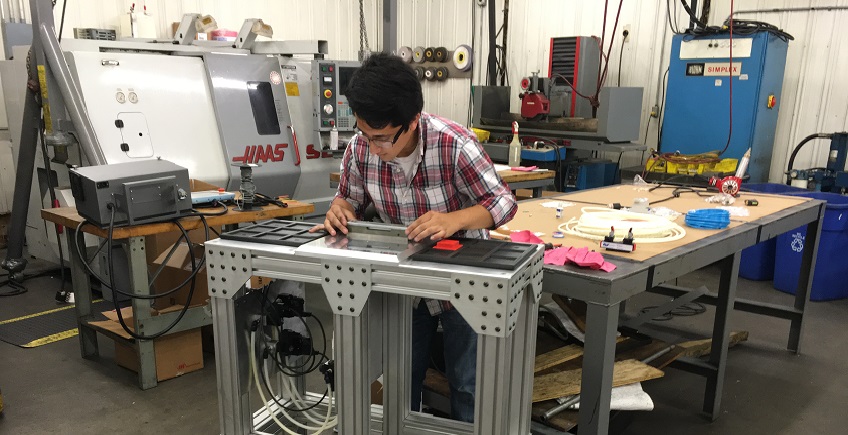

When they first started, they jumped into an automation project for our division in Harrison. While they’re too young to work on the plant floor, they were able to work with 3D modeling, grow in their understanding of the die casting process, and perform computer work that assisted in perfecting our Automation Training Center.

This summer they’re using their skills to integrate a collaborative robot with a CNC machine. These robots offer multiple benefits to a plant in terms of safety and cost effectiveness. When they’re programmed to work with CNC machinery, it allows us to offer a more finished product for customers. So the projects these interns are exposed to are educational for them and beneficial to the company.

In addition to working with our 3-D printers and robotics, Juan and Noah have participated in safety meetings and other day-to-day activities within the company – giving them a good sense of the business environment and making them smarter about the industry as a whole.

Each summer, the internship culminates in a presentation to the entire home office that includes a summary of what they’ve learned. When asked about their experiences with Pace so far, Juan said, “Pace has offered us a great opportunity, especially for someone our age. I’d like to offer them a big thank you!” Noah was quick to agree.

These two students get credit for bringing the idea of the internship to Pace. They also inquired about funding for their school’s robotics program, which was just getting started. Pace was pleased, and continues to be excited about, supporting and encouraging these young engineers, as well as others who share the same passion. Internships and sponsorships are investments we want to continue to make. In fact, we’d like to branch out into other communities where we have divisions and offer similar programs in the years ahead. We see value in the next generation of makers. They’re our future. And based on what we’ve experienced so far, we’re in good hands.