Top 5 Tips for Die Casting

Die casting can be a tricky thing to master. That’s why at Pace Industries, our experts are here helping through every phase of the process. Pace is constantly working to provide uncommon solutions to customers, and one example is the extensive product design assistance we offer.

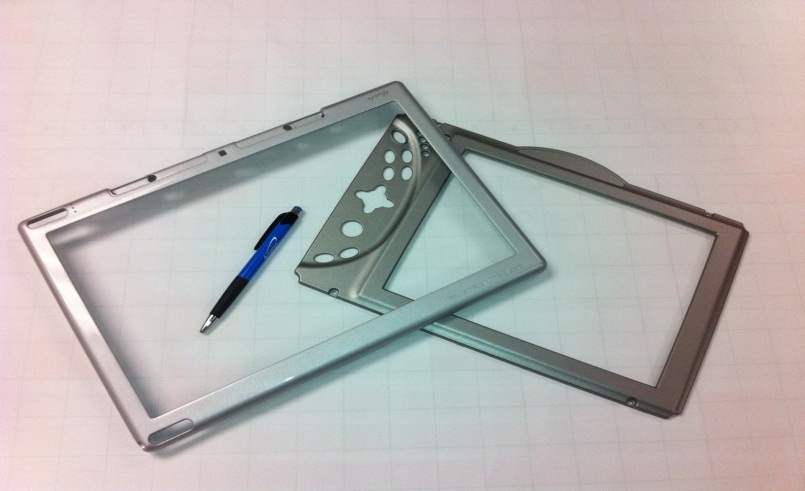

We work with our customers on the design of their castings to incorporate features that will maintain functionality while optimizing features that enable the casting to be easier to produce. This allows our customers to receive a casting from Pace that is designed to minimize their cost while allowing Pace to minimize our production costs.

Customers often know what they want functionally and we know how to make a casting that will meet those needs. Here are our top five tips that can help you understand our process and the reasoning behind the design guidance we provide.

TIP #1: Maintain a uniform wall thickness across the casting. (While this is not always possible, try to keep the variations in wall thickness to a minimum.)

• This improves metal flow and the filling of the casting for better quality. It also minimizes dimensional variation due to the differences in cooling rates in the casting walls.

TIP #2: Corner radii (outside corners) and fillet radii (inside corners) on the casting should be as large as possible.

• This improves the filling of the casting for better quality and increases die life due to decreasing of the degradation of the die steel in sharp corner areas.

TIP #3: Include draft (tapered walls) in the casting design. You should have more taper (draft) on the inside walls of the casting than you do on the outside walls of the casting.

• Draft is required in order to remove the casting from the die. (This the same reasoning used in the design of muffin tins, which have tapered walls to aid in removing the muffins.) The reason for more draft on the inside walls is that the casting alloy shrinks as it solidifies. Castings tend to get smaller and fit more tightly onto the inside of the casting. The increased draft then allows for easier removal of the casting from the die.

TIP #4: Keep critical dimensions on the same side of the die.

• Since the die has moving components, dimensions that are based on more than one component will have more variation than dimensions that are based on features in a single die component. Greater variation in dimensions will require larger tolerances, which may not be acceptable to the function of the casting. When that happens, it requires added operations on the casting to meet tolerances, which will result in added costs to the customer. (Something we always want to avoid!)

TIP #5: Avoid undercuts, if possible.

• Undercut geometry cannot be cast in a standard die cast die. This undercut requires the addition of a moving die member called a “slide” in order to cast this piece of the casting geometry. The added “slide” increases the cost of the cast die. The undercut geometry also affects the amount of time required to make the casting, which increases the cost to the customer.

At Pace, we are here to provide hands-on assistance. We can help you understand the design process and what will ultimately be the best fit for your casting needs. We also offer casting design seminars at customer locations where we meet with product design engineers in an informal, educational setting to provide a better understanding of what designs work well for die casting.

Our first priority is always to provide our customers with high-quality products at competitive prices. Working together with our customers, we can help develop casting designs that satisfy functionality and castability requirements.

My name is Eve Mayer and I don’t work in die casting. I am an author who works in social media, the world of words where everything we create can neither be touched nor felt with the human hand.

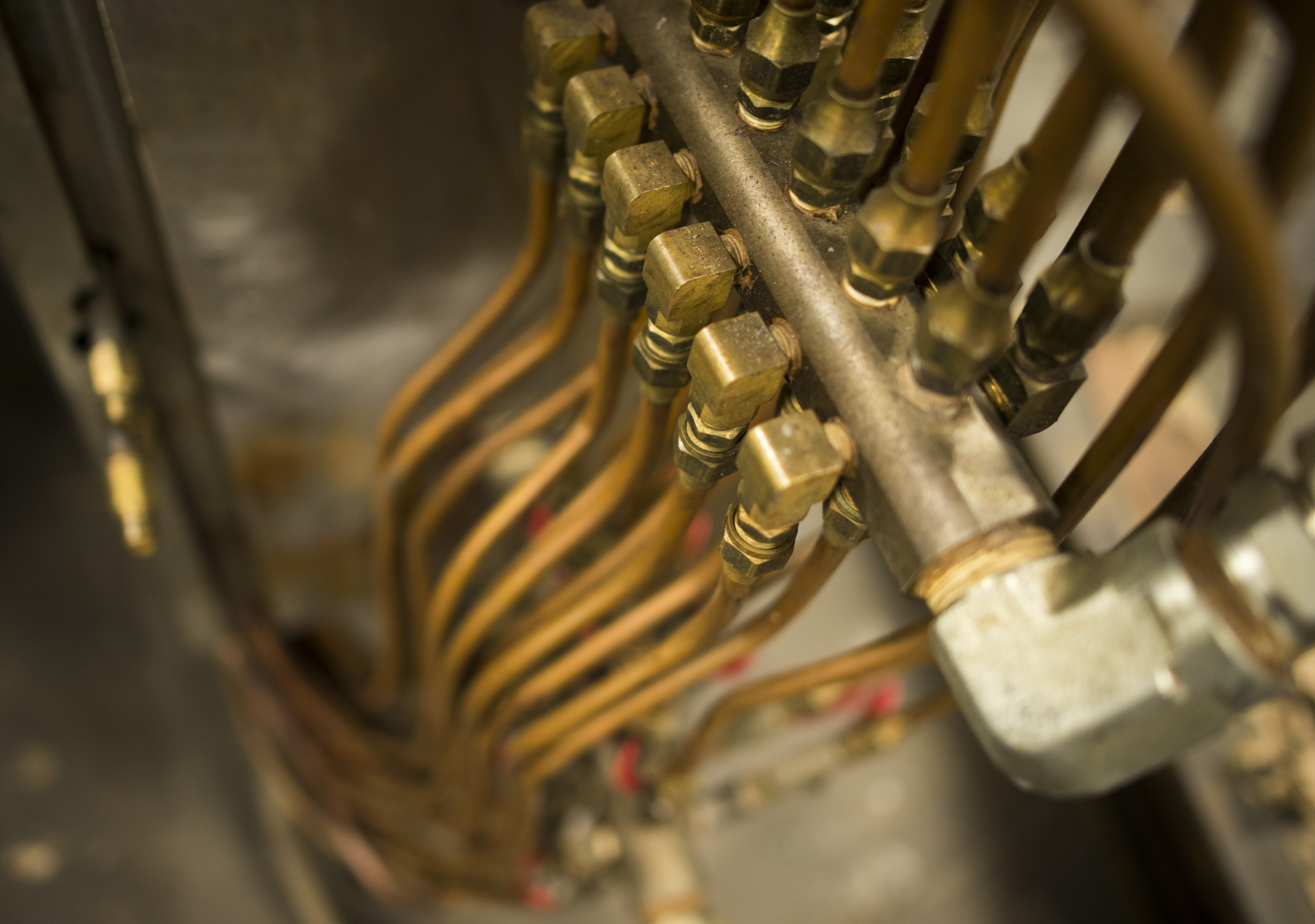

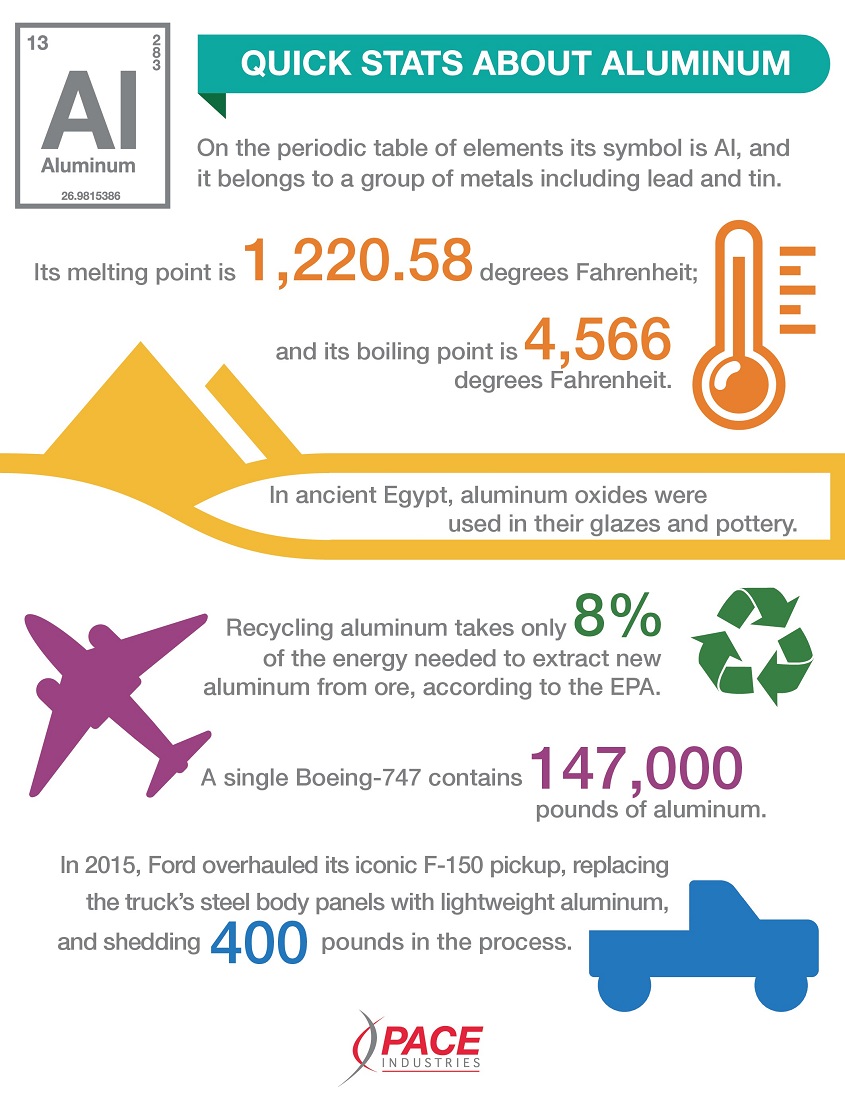

My name is Eve Mayer and I don’t work in die casting. I am an author who works in social media, the world of words where everything we create can neither be touched nor felt with the human hand. Die casting isn’t a glamorous industry. It is a detailed, precision necessary industry where hard working people use machines to carefully craft metal pieces like auto parts, light bulb bases, motorcycle pieces, back sides of carpeting and bed springs. My view is probably skewed as I toured an aluminum factory and die casting is done with several different types of metals like zinc, magnesium and aluminum.

Die casting isn’t a glamorous industry. It is a detailed, precision necessary industry where hard working people use machines to carefully craft metal pieces like auto parts, light bulb bases, motorcycle pieces, back sides of carpeting and bed springs. My view is probably skewed as I toured an aluminum factory and die casting is done with several different types of metals like zinc, magnesium and aluminum. Some metal pieces need to be pretty and some don’t. For example, if you are having a piece built for the inside of a car engine that someone will never see once built, you don’t want to spend money on making this piece pretty, it just needs to be functional. Another metal piece might be on a motorcycle but sit on the outside of the bike in full view so it needs to be functional but also have a nice look to it. This is where specific processes that deal with painting or chroming parts comes into play.

Some metal pieces need to be pretty and some don’t. For example, if you are having a piece built for the inside of a car engine that someone will never see once built, you don’t want to spend money on making this piece pretty, it just needs to be functional. Another metal piece might be on a motorcycle but sit on the outside of the bike in full view so it needs to be functional but also have a nice look to it. This is where specific processes that deal with painting or chroming parts comes into play.