LIGHT METAL HIGH PRESSURE DIE CASTING

EXTENSIVE DIE CASTING EXPERIENCE

Delivering complex and cosmetic castings for a large array of part sizes and weights.

STATE OF THE ART EQUIPMENT

STATE OF THE ART EQUIPMENT

CORE SEGMENTS OF HIGH PRESSURE DIE CASTING

HIGH VOLUME

Our die casting capabilities are vast with over 250 die casting machines ranging from 60 to 3,000 tons, giving us the ability to not only provide a large range of light metal casting sizes and weights, but also to support the high-volume demand from our customers.

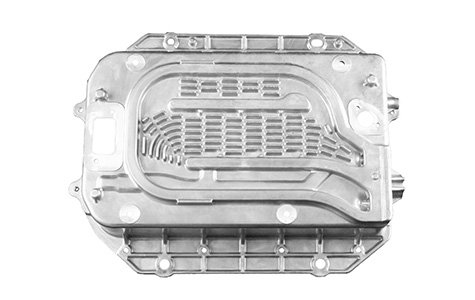

COMPLEX CASTINGS

At Pace Industries we offer unique solutions for complex castings across three primary materials; aluminum, magnesium and zinc, utilizing uncommon technology and expertise. From thin wall castings, to cast-in tubes, loose piece castings to castings with steel inserts Pace has an innovative solution for your casting needs.

COSMETIC CASTINGS

Our technical expertise, meticulous approach to tool & die maintenance and leading casting capabilities produce high quality premium finished parts in a mass production environment.

The quality of the surface finish allows for smooth application of our portfolio of coating and finishing capabilities.

CORE SEGMENTS OF HIGH PRESSURE DIE CASTING

HIGH VOLUME

Our die casting capabilities are vast with over 250 die casting machines ranging from 60 to 3,000 tons, giving us the ability to not only provide a large range of light metal casting sizes and weights, but also to support the high-volume demand from our customers.

COMPLEX CASTINGS

At Pace Industries we offer unique solutions for complex castings across three primary materials; aluminum, magnesium and zinc, utilizing uncommon technology and expertise. From thin wall castings, to cast-in tubes, loose piece castings to castings with steel inserts Pace has an innovative solution for your casting needs.

COSMETIC CASTINGS

Our technical expertise, meticulous approach to tool & die maintenance and leading casting capabilities produce high quality premium finished parts in a mass production environment.

The quality of the surface finish allows for smooth application of our portfolio of coating and finishing capabilities.

MATERIALS

The materials cast include a variety of aluminum, magnesium and zinc alloys to suit every application and mechanical properties.

ALUMINUM

Pace has aluminum die casting machines ranging from 400 to 3,000 tons, giving us the ability to provide a large range of aluminum casting sizes and weights to serve nearly any industry and application. Aluminum die cast parts are lightweight, corrosion resistant and have a wide range of surface finishing options.

MAGNESIUM

Pace has extensive magnesium die casting knowledge and expertise, partnering with customers on the distinctive benefits of magnesium die casting to suit their needs. Magnesium offers a perfect combination of light weight, rigidity and resistance to wear for diverse die cast part applications.

ZINC

Pace offers a variety of zinc die casting approaches that range from the ability to produce small, miniature zinc die castings to larger, conventional castings. Zinc provides unique advantages in many die casting applications that include a combination of strength, ductility, impact strength, finishing characteristics and tooling that has high resistance to catastrophic failure.

MATERIALS

The materials cast include a variety of aluminum, magnesium and zinc alloys to suit every application and mechanical properties.

ALUMINUM

Pace has aluminum die casting machines ranging from 400 to 3,000 tons, giving us the ability to provide a large range of aluminum casting sizes and weights to serve nearly any industry and application. Aluminum die cast parts are lightweight, corrosion resistant and have a wide range of surface finishing options.

MAGNESIUM

Pace has extensive magnesium die casting knowledge and expertise, partnering with customers on the distinctive benefits of magnesium die casting to suit their needs. Magnesium offers a perfect combination of light weight, rigidity and resistance to wear for diverse die cast part applications.

ZINC

Pace offers a variety of zinc die casting approaches that range from the ability to produce small, miniature zinc die castings to larger, conventional castings. Zinc provides unique advantages in many die casting applications that include a combination of strength, ductility, impact strength, finishing characteristics and tooling that has high resistance to catastrophic failure.

GET A QUOTE

Tell us about your upcoming project and our team will be in touch with you soon.

GET A QUOTE

Tell us about your upcoming project and our team will be in touch with you soon.