Learning and Growing: Pace Further Adapts Competitive Advantage Strategy

Business Excellence is Pace’s systematic approach to identifying and eliminating waste through continuous improvement and making products that meet our customers’ needs. As its director, Bill Turner is focused on the company’s wins, as well as the growth opportunities that become apparent after setbacks.

As 2016 ended, he reflected on the past year and looked ahead to Business Excellence in 2017:

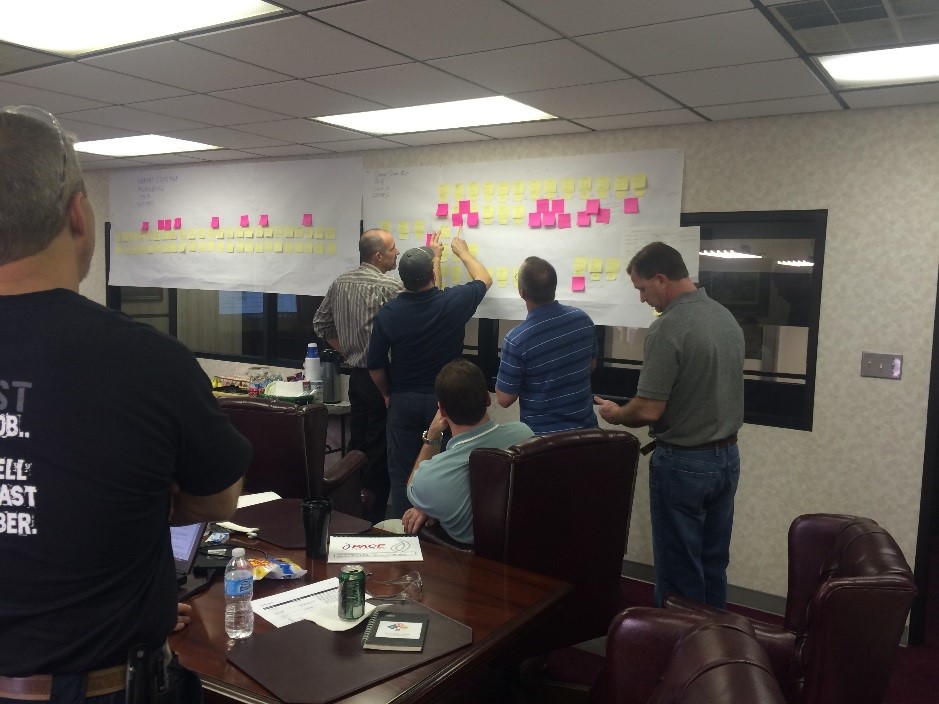

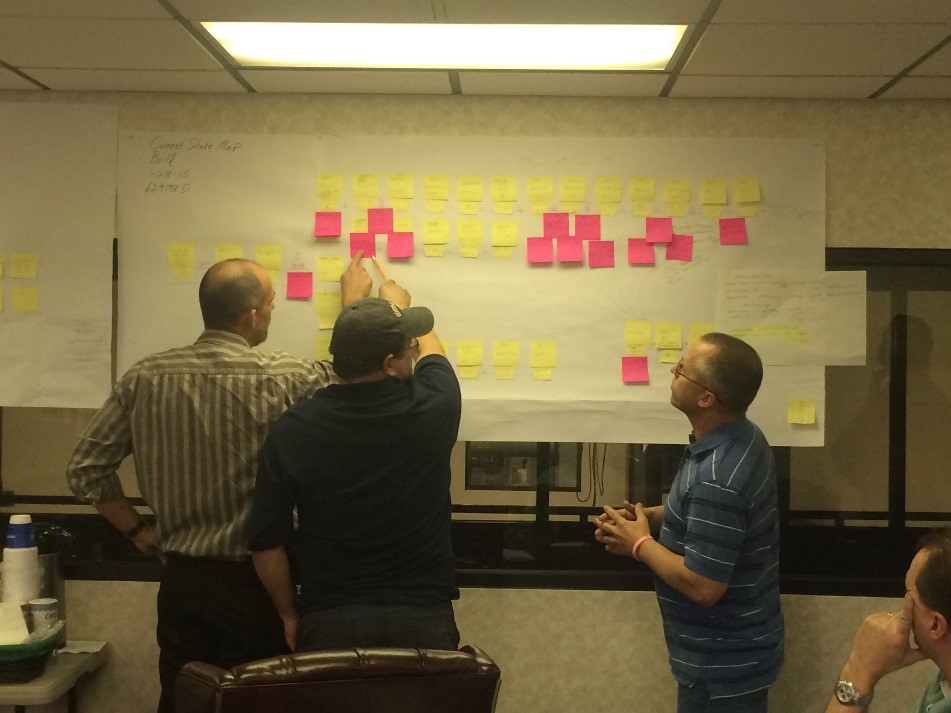

Strategy Deployment (SD) is a structured process that motivates us to work on those things paramount to the success and longevity of our business, including safety, quality, delivery, inventory and cost. It has been an integral part of our business for 10 years. In 2017, SD will continue to be key in helping us achieve a compelling competitive advantage. Associates from all levels of our company participate on multi-functional teams to achieve the goals established through this process. From there, teams are empowered to develop and execute action plans, measure progress and resolve problems. Through this, we build a culture of continuous improvement through associate engagement, teamwork and problem solving.

This year provided evidence that this strategy is positively affecting our work. In 2016, there were several new product introductions across the business, many of which were in the automotive industry. Serving this industry’s customers can be a challenge due to the complexity of the parts and their stringent quality requirements. Despite those difficulties, in 2016, we improved our parts and customer satisfaction significantly increased, allowing for a growth in the automotive segment of our business. Our quality was better though the work was more complex. We consider this a great success story!

So where is Business Excellence going in 2017? First, we will reinforce our commitment to SD by engaging even more associates in the process. Second, we will be expanding the utilization of ongoing improvement methodologies and tools, including value stream mapping, 5S, standard work, poka-yoke, SMED and kanban. We need to take advantage of these proven improvement techniques. And third, we will remain diligent problem solvers.

In 2017, we will be relentless in our pursuit of achieving a compelling competitive advantage.

A team at Mangas Tool & Die complete a value stream mapping exercise as part of Strategy Deployment.